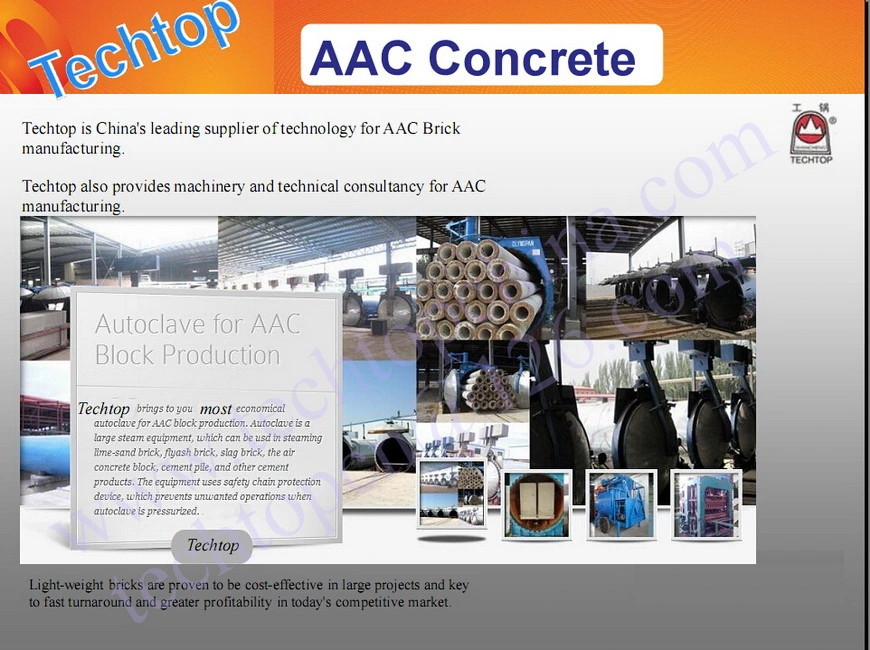

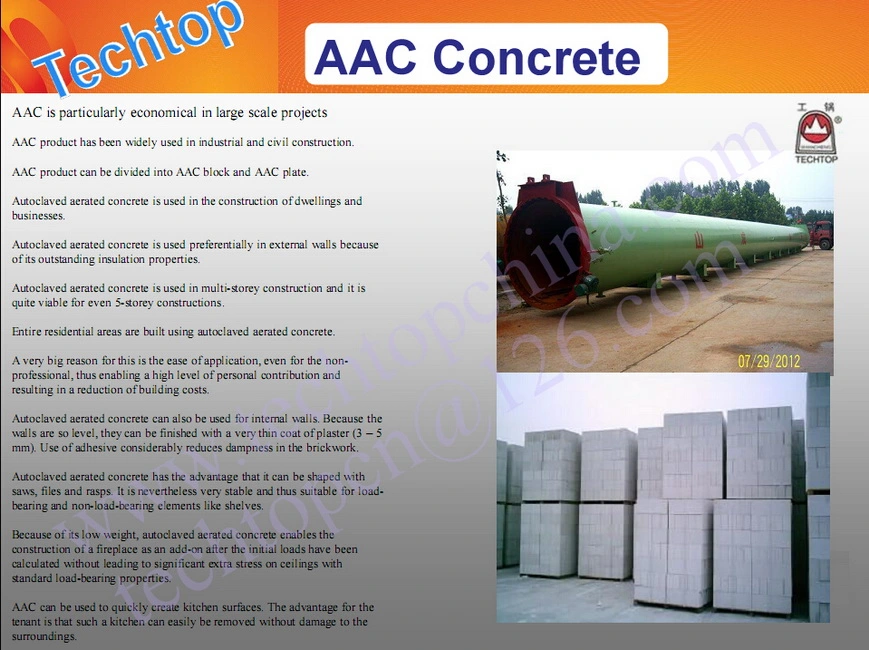

Autoclaved Aerated Concrete (AAC) Light Weight Block Production Line

Autoclave for Brick Production Line Autoclaved Aerated Concrete Production introductionThe Autoclave is also called stea

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 2000X13000mm |

| Type | Autoclave |

| Certification | CE, ISO |

| Structure | Horizontal |

| Control System | Automatic/Manual |

| Glass Washing Machine Type | No |

| Glass Edging Machine Type | No |

| Grinding Head Number | No |

| Condition | New |

| Method | Hydraulic Pressure |

| Place of Origin | Shandong, China |

| Brand Name | Techtop |

| Voltage | 220V/380V, 380V/220V |

| Warranty | 1 Year |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Working Medium | Steam |

| Material | Carbon Teel |

| Length | Customizable |

| Capacity | Customizable |

| Transport Package | International Standard |

| Specification | GB |

| Trademark | TECHTOP |

| Origin | Taian |

| HS Code | 73110090 |

| Production Capacity | 500sets/Year |

Product Description

Autoclave for Brick Production Line Autoclaved Aerated Concrete Production introductionThe Autoclave is also called steam autoclave curing kettle, steam pressure autoclave, it is a bulky, heavy weight of large pressure vessels. Autoclave has a widely usage, mainly used in aerated concrete block, concrete pipe pile, sand-lime brick, fly ash bricks, plaster and other building materials of high strength autoclave curing, complete water CaO-Si02-H2O in the kettle thermal reaction. It is also widely used in rubber products, bricks invade oil seepage coal, steam curing comply glass, pulp cooking, cable vulcanization, as well as chemical, pharmaceutical, aerospace industry, and other required pressure steam curing production projects.Structure category1. The main pressure parts materials: Simplified kettle lid using 16MnR steel plate in line with GB6654 standard requirements.2. Open the door: through type or make-ended. Installed reactor lid at both ends is the through-type one, make-ended means on one end of the autoclave cover.3. Kettle lid open way: Tooth quick open structure, drive sub-manual, electric, pneumatic and hydraulic transmission. And equipped with a kettle door open and close safety interlocks.4. The main part of the autoclave kettle body mainly consists of kettle lid devices, oscillating means, hand reducer, safety devices, supports, insulation, sealing devices, instrument pipe valves and other components. Affiliated portion includes drainage and electric control box.

Related Products

-

![Heavy Duty Medical Action Infectious Waste Autoclaving Bag Red Plastic Disposable Bio Hazard Medical Waste Bag]()

Heavy Duty Medical Action Infectious Waste Autoclaving Bag Red Plastic Disposable Bio Hazard Medical Waste Bag

-

![High Quality Disposable Autoclaving Sterile Universal Plastic Laboratory Supplies Extended Length Racked Pipette Tips with Filter 10UL]()

High Quality Disposable Autoclaving Sterile Universal Plastic Laboratory Supplies Extended Length Racked Pipette Tips with Filter 10UL

-

![Donyue AAC Light Weight Brick Production Plant]()

Donyue AAC Light Weight Brick Production Plant

-

![Cheap Price Sand Fly Ash Lightweight AAC Autoclaved Aerated Concrete Block Making Machine Plant Small Capacity]()

Cheap Price Sand Fly Ash Lightweight AAC Autoclaved Aerated Concrete Block Making Machine Plant Small Capacity