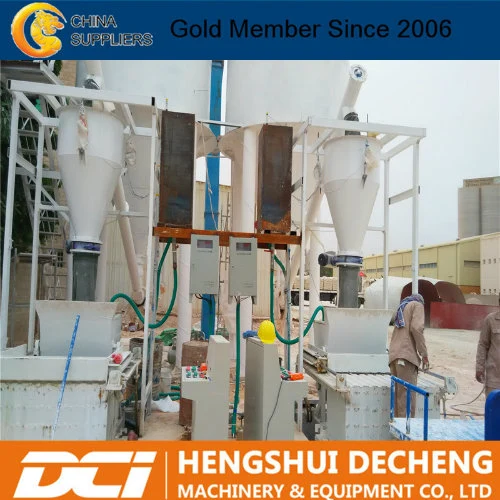

Practical and Economic AAC Gypsum Wall Block Production Line

Our company specially designs and manufactures complete sets of building materials equipments, such as paper surface gyp

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | DCQ004 |

| Machine Color | Blue or as Your Requirement |

| Machine Capacity | 100000-300000m2/Year |

| Brick Raw Material | Gypsum Material |

| Processing | Brick Molding Machine |

| Method | Hydraulic Pressure |

| Automatic Type | Yes |

| Warranty | 12 Months |

| After Sales Service Provided | Yes |

| Transport Package | Seaworthy Packing |

| Specification | ISO9001 |

| Trademark | DCI |

| Origin | Hebei China |

| HS Code | 847480909 |

| Production Capacity | 200 Sets Per Year |

Product Description

Our company specially designs and manufactures complete sets of building materials equipments, such as paper surface gypsum board production line, gypsum powder production line (natural gypsum and chemical gypsum), fiber cement board production line, calcium silicate board production line, cement production line, AAC block production line, stone production line, etc. Certainly we also supply single machines, spare parts and wearing parts for these production lines; at the same time, we produce some raw materials for the production lines, such as modified starch, foaming agent, glue, etc.

Our company has well-experienced professional engineers and technical teams to ensure our clients with high-quality equipments. The well-skilled installation and commissioning team and high-quality process technologists provide our clients both at home and abroad with full set of technical services to make our clients"buy with reassurance and use with gratification". In recent years, our company has completed building materials equipment projects in the Middle East, Central Asia and Eastern Europe, etc, and has got highly praises for both product quality and after-sale services.

| 1.Brief introduction 1) Gypsum Block is a kind of light walling material, produced by Building Gypsum as main material, adding suitable light materials & additives, mixing with water and then being molded and dried. 2) It is a environment-protection and energy-saving green product generalized by our country. According to its structural form, it is divided into hollow Gypsum Block and solid Gypsum Block. 3) It is widely used in building as inner partition wall, because of its advantages of light weight, exact dimension, fire-proof function, shock-proof function, heat preservation and heat insulation, adjusting indoors dryness and humidity, good capability of manufacture and convenient construction, etc... |

2.Main Parameters 1).Final block/brick specification: Length:666mm; Width:500mm; Thickness:80mm,90mm,100mm,120mm,150mm; 2).Product performance: Air sound insulation: 40.5db; Fire resistance:186min; Flatness: ≤1mm/m2; 3).Forming Block number:5-7mold/hour 4).Composed equipments: molding machine;mixer;hydraulic control system;screw converyor 5).Voltage: 380V(+/-10%~15%) 6).Power: 19KW |

3.Advantage 1).Super-strong steel structure made of extensive original parts, ensuring more stability and reliability for the concrete block machine body. 2).The whole process uses a PLC control system of human-machine interface, easy to analyze the chance signal, ensure the best operation effect. 3).High-efficient and super-strong vibration system, realize vertically synchronous vibration, frequency conversion, and braking, thus greatly increase product compactness and mould-box service life. 4).The cloth system adopts semi-closed screen reticular rotational feeding unit to feed materials forcedly, with evenness and even speed, ensuring product intensity. 5).Fitted with special hydraulic loading unit, readily realize mass and automatic production, saving a great deal of human power, maintenance field, and circulating fund investment |