Progeneus Cellulose Fiber Cement Panel Autoclaving

Progeneus high density non-asbestos fiber cement board is made by cellulose fiber, quartz sand, Portland cement and wate

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | H-11mm |

| Surface Finishing | Sanding |

| Edge | Square |

| Shape | Square |

| Refractory Temperature | Over 2000 ℃ |

| Usage | Furniture, Building, Flooring |

| Asbestos | 100% Asbestos Free |

| Maximum Size | 1220X4880mm |

| Wet Expansion | </=0.23% |

| Thickness Tolerance | +/-0.2mm |

| Water Absorption | <28% |

| Transport Package | Wooden Pallets |

| Specification | 1220x2440mm |

| Trademark | Progeneus |

| Origin | China |

| HS Code | 6811820000 |

| Production Capacity | 20000000 M2/Year |

Product Description

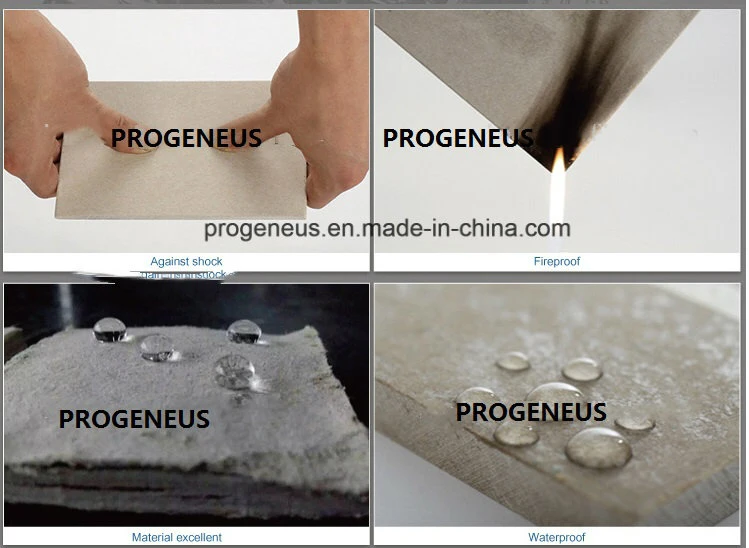

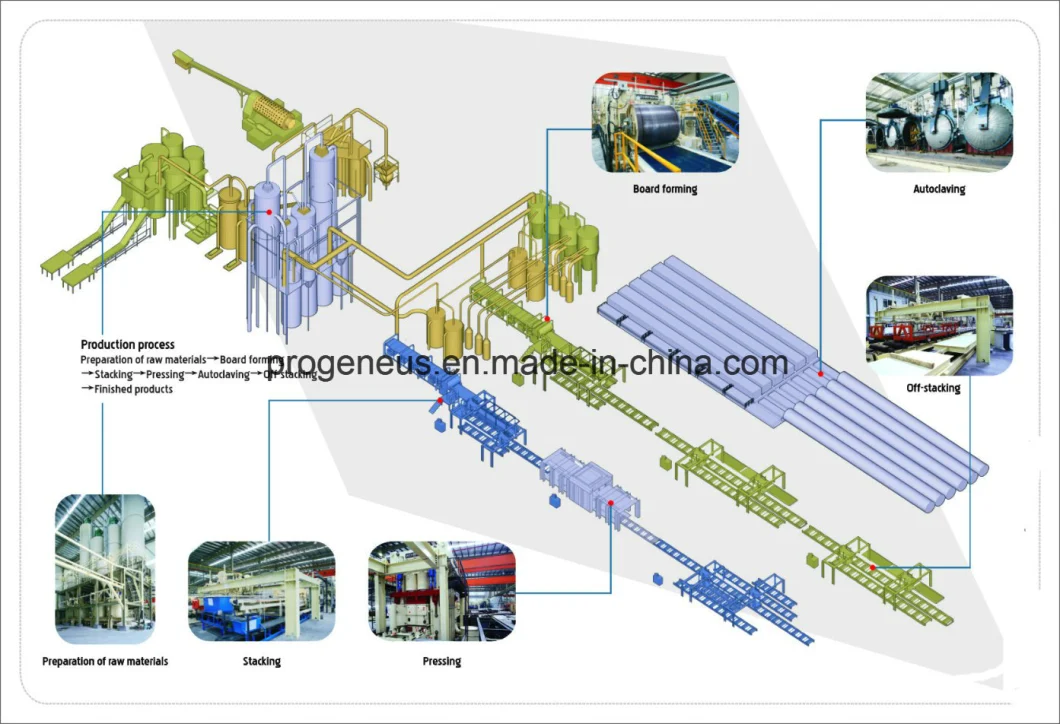

Progeneus high density non-asbestos fiber cement board is made by cellulose fiber, quartz sand, Portland cement and water. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons compressing machine, and autoclaved under high temperature and pressure. It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and eco-friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specification

| Product Name | Compressed Fiber Cement Board |

| Raw Materials | Cellulose Fiber, Quartz Sand, Portland Cement |

| Standard Size | 1200X2400mm/1220X2440mm |

| Maximum Width | 1250mm |

| Maximum Length | 4880mm |

| Thickness | 4-30mm |

| Density | 1.4-1.7g/cm3 |

| Wet Expansion | ≤0.23% |

| Water Absorption | ≤28% |

| In-combustibility | Incombustible Grade A1 |

| Water Penetration | Back side without water drop after 24 hours |

| Bending Strength | Air dried condition:≥16Mpa; Saturated Condition ≥13Mpa |

| Radioactivity | Decorative materials Class A |

| Asbestos | 100% free of asbestos |

| Frost resistance | No layers and crack after 25 cycles under freezing and thawing |

Main Characteristics | Eco-friendly materials |

| Excellent Strength and toughness | |

| Waterproofing and fireproofing | |

| Antisepsis and moth-proofing | |

| Good acoustic insulation and weather resistance | |

| Good Thermal and heat insulation | |

| Durability and long lifetime |

Product Advantages

1. Stylish and VersatileEasily design a house to suit varying ground levels on a build site and have greater flexibility in terms of mixing and matching a diverse range of exterior styles without changing the underlying method of construction.

2. Durable and Low MaintenanceReinforced fiber reinforced cement products are impact resistant and weatherproof. They don't crack, swell or warp like wood so they can hold dark colours and for longer.

3. Thermal EfficiencyUsing lightweight, cement composite building materials can deliver significant benefits on warm days because of the materials' inherent ability to cool rapidly at night. This can give relief to sleeping areas in the night.

4. Increased Speed of ConstructionFiber cement products makes the building process simpler and faster by reducing the need for wet trades on site. You can achieve a greater installation rate per day with most products, getting you to lock up faster and in the home sooner. A great benefit for both builders and homeowners!!

5. Space MaximisationYou can generate greater internal floor area and living space within a home because the walls can be thinner than traditional construction methods. Composite materials fix direct-to-frame reducing wasted space, unlike alternative construction methods.

Production Flow

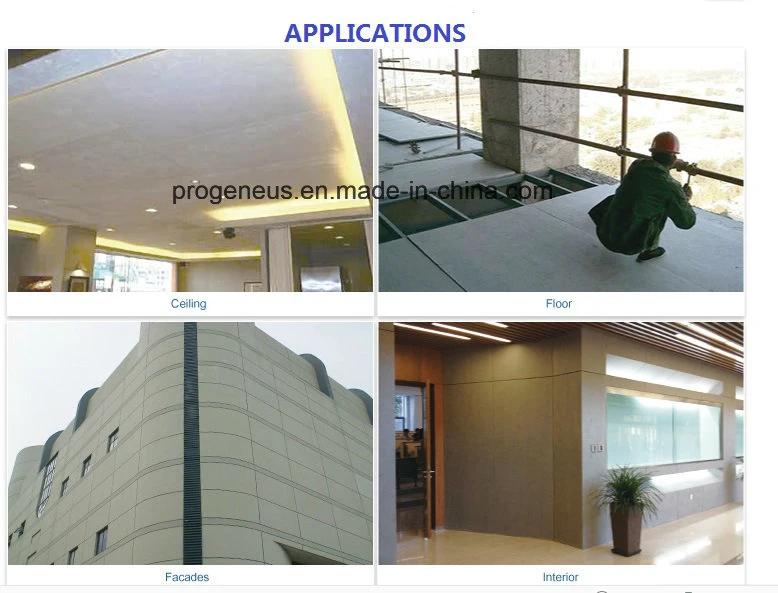

Application Field

It's an ideal material for internal wall and external wall design.The products are diverse, coming in numerous profiles and finishes for a range of interior and exterior building applications that suit most architectural styles. It can be used on either timber or light gauge steel framed buildings. Due to smooth surface, it can be painted, wallpapered, partly/fully tiled to create a wide range of design looks.

Export Packing

The fiber cement board is packed by standard wooden pallet wth corner protection to make sure goods arrive destination safely..

Projects

Order Guide

1. Inquiry-Professional quotation.

2. Confirm the price, lead time, artwork, payment term etc.

3. Progeneus sales send the Proforma Invoice with freedom seal.

4. Customer makes the payment for deposit and send us Bank receipt.

5. Initial Production Stage-inform the clients that we have got the payment, and will make the samples according to your request, send you photos or samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time.

6. Middle Production-send photos to show the production line which you can see your products in producing. Confirm the estimated delivery time again.

7. End Production-mass production products photos and samples will send to you for approval. You can also arrange the third party inspection if necessary.

8. Clients make payment for balance and ship the goods .Also can accept payment term-balance against B/L Copy or L/C payment term. Inform the tracking number and check the status for clients.

9. Order can be say "finish" when you receive the goods and satisfy with them .

10. Feedback to Progeneus about quality , Service, Market Feedback & Suggestion. And we can do better.

Service

1,24-hour ResponseWe responds any request from our clients within 24 hours, saving your time and labor.

2,Supporting SystemThe system consists of claims systems, technical support system, inquiry system and ordering following system. The system will provide after-sales service in full range.

3,Free TrainingWe provide free training to all of our clients and distributors. The training will give you ample knowledge of our product, and make it easy for your work.

4,Free Storage AreaWe are providing free storage area to our client,to achieve mix loading purposes.