Qt12-15 High Production Cement Concrete Hot Sale Hollow Solid Fly Ash AAC Block Brick Production Line

QT12-15 Fully Automatic Hydraulic Concrete Cement Hollow and Paver Brick Block Making Machine We had exported to more th

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | QT12-15 |

| Certification | CE, ISO |

| Customized | Customized |

| Automatic Grade | Automatic |

| Type | Hydroforming |

| Cycle Time | 15-25s |

| Pallet Size | 1350X900mm |

| Hydraulic Pressure | 21MPa |

| Vibration Form | Platform Vibration |

| Automatic | Yes |

| Dimension(L*W*H) | 9350X2520X2950mm |

| Weight | 12500kgs |

| Transport Package | Container |

| Trademark | HF |

| Origin | China |

| HS Code | 8474802000 |

| Production Capacity | 22400 PCS for 8′′ Block Per Day |

Product Description

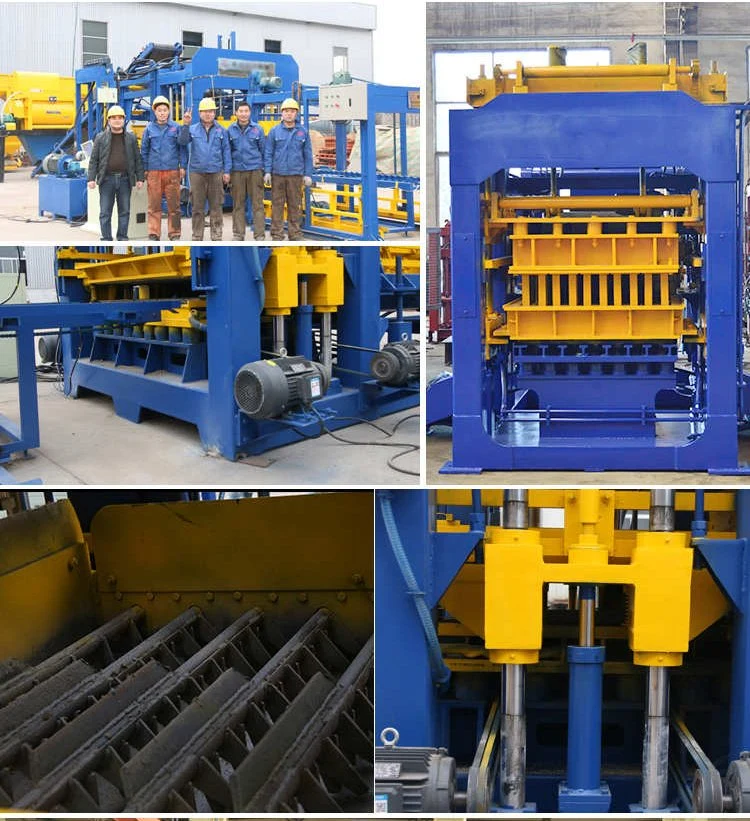

QT12-15 Fully Automatic Hydraulic Concrete Cement Hollow and Paver Brick Block Making Machine

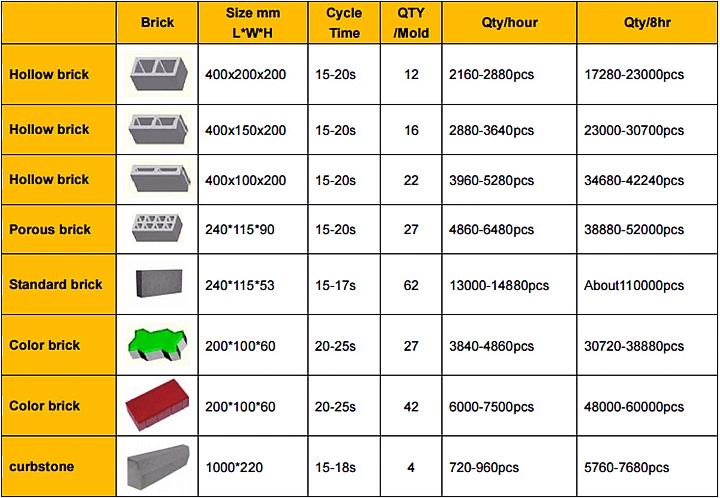

| QT12-15 block making machine is latest developed equipment product, which is a special-purpose equipment for making building block making machine. The material of this machine can be flyash, slag, gangue or the others industrial waste, river sand, gravel, cement etc. Makes different sizes of hollow blocks, porous blocks, curbstone, pavement blocks, grass blocks, slope-protecting blocks, ring-tree blocks etc. If add color machine, it can make layering blocks.This block machine is mechanical hydraulic PLC controlled synthesis technique equipment. Its characteristic is high efficient, easy-operated and easy-maintained. Block molding mainly by hydraulic, machinery as sideline, vibrate and press to finish molding blocks. The compressive strength of all blocks more than 21 MPa, compactness is high, impermeability and freeze resistance is better, and excellent capacity of sound insulation, heat insulation, insulation.external dimensions are precise.QT12-15 type block machine adopts gantry frame type structure, made by super super steel,strong and shock resistant,very reliable.The design adopts the driving type material storage mode with independent foundation, to send the material when it is needed at chinablockmachine.en.made-in-china.com wave swing type of material feeding device,with good feeding effect.Cartridge type welding mold,adopts qualified manganese steel by carburizing and quenching. no transformation and no damage after using 100000times.It can make the simple production line with PLD1200 batching machine,JS500or JS750 mixer,8m conveyor belt and stacker. |

| Main Technical Specifications | |

| Overall Dimension | 9350x2520x2950mm |

| Rated pressure | 21Mpa |

| Main vibration form | Platform vibration |

| Cycle Time | 15-25 seconds |

| Vibrating Frequency | 2800-4500 rolls/minute |

| Motors Power | 63.5 KW |

| Pallet Size | 1350x900mm |

| Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applied Products | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields | widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

Our service

1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation.Countries or regions with unstable political situation or in the throes of wartime are not included in our plan.

2) Train the users to command the equipment and guide them for safe production.

3) Explain the routine maintenance of equipment carefully and remove common faults.

4) We are responsible for all the repairs that caused by our quality problems within one year's warranty. (We will provide one set of spare parts/wear & tear parts free of charge with shipment.)

5) For some countries whose visas are difficult obtained, customers can also send their technicians to our company to receive free guidance and training.

6) Accept suggestions for improvement put forward by customers an earnest way. In accordance with changes of the market, provide the products and services to meet the user's needs and create value for them.

7) We will make every effort to solve your problems, and your success will add new CONFIDENCE.

If you interested in our block machine, please feel free to contact me.

Related Products

-

![100, 000-500, 000 M3 Production Line for AAC Block/ Panel]()

100, 000-500, 000 M3 Production Line for AAC Block/ Panel

-

![Small Biohazard Bag Autoclaving Envelopes 95kpa Biohazard Specimen Transportation Bag with 7 Slotted Absorbent Pocket Sleeve Ues Medical Lab]()

Small Biohazard Bag Autoclaving Envelopes 95kpa Biohazard Specimen Transportation Bag with 7 Slotted Absorbent Pocket Sleeve Ues Medical Lab

-

![2022 Big Output AAC Small Block and Panel Making Plant in Thailand]()

2022 Big Output AAC Small Block and Panel Making Plant in Thailand

-

![China Mobile Concrete Batching Mixing Plant 25/35/40/60m3 From Manufacturer]()

China Mobile Concrete Batching Mixing Plant 25/35/40/60m3 From Manufacturer