AAC Brick Making Machine, AAC Plant

1.Our Company Founded in October 1998,Shandong Sunite Machinery Co.,Ltd is a professional manufacture of aerated concret

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | aac plant |

| Warranty | One Year |

| Transport Package | General Packing |

| Specification | ce, iso9001 |

| Trademark | shandong sunite machinery |

| Origin | Shandong |

| HS Code | 84748090 |

| Production Capacity | 50000 Cbm Per Year |

Product Description

1.Our CompanyFounded in October 1998,Shandong Sunite Machinery is a professional manufacture of aerated concrete block equipment, aerated concrete wallboard equipment and autoclaved brick equipment in Shandong province.

With the full implementation of ISO9001:2008 Quality Management Systerm, Shandong Sunite Machinery was awarded with the title of Chinese Top Brand and Chinese Famous Brand and High-Quality Product in 2013.Besides, our company has also won several product patent awards.

2. Autoclaved Aerated Concrete

Autoclaved Aerated Concrete (AAC) is a siliceous material (sand, fly ash,gangue etc.) and calcareous materials (lime, cement) as the main raw material, mixing with foaming agent(aluminum powder) by mixing, casting, pre-curing, cutting, autoclave process made of light weight concrete products..

As a result of its excellent properties, AAC is used in many building constructions.

3. The material batching rate

NameUnitCement Lime Sand

Sand%55-65

Cement%10-20

Lime%20-30

Gypsum%2-3

Aluminum powder paste(600kg/m3)1/100008

Water & material rate 0.65-0.75

Casting systemOC35-38

Aluminum mixing timeS30-40

nameunitCement lime fly ashflash%65-70cement%6-15lime%18-25gypsum%3-5Aluminum powder paste(600kg/m3)1/100008Water & material rate 0.60-0.65Casting systemOC36-40Aluminum mixing timeS30-40

Remark:the exact batching rate is adjustable according to the raw material locally.

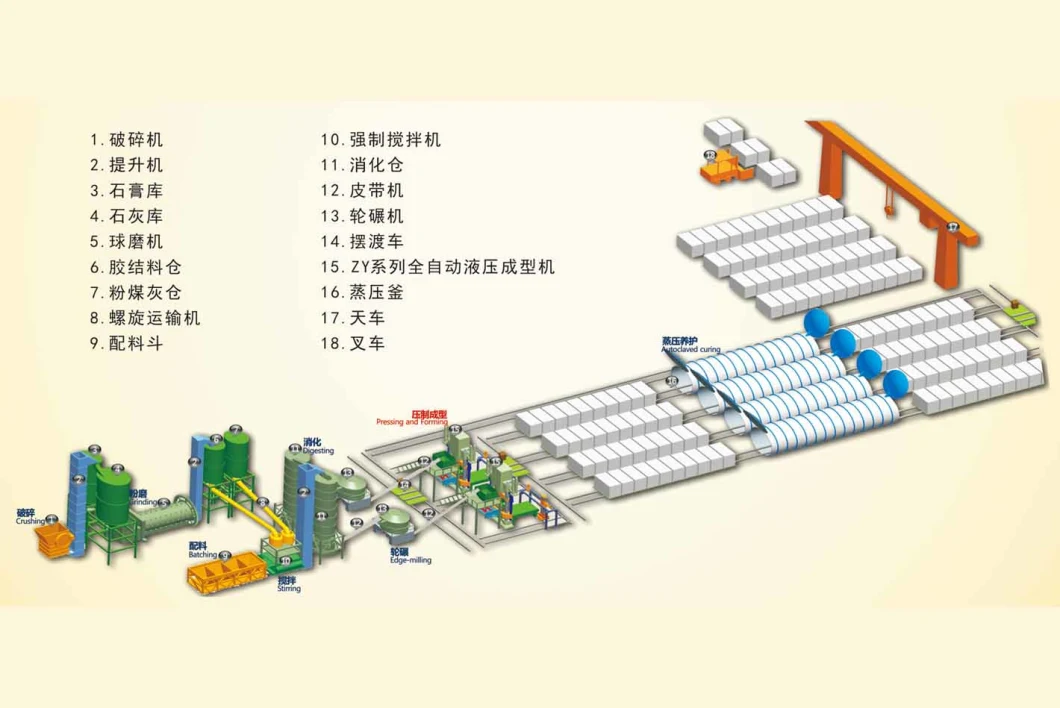

4.AAC production plant

1.Our Company

Founded in October 1998,Shandong Sunite Machinery is a professional manufacture of aerated concrete block equipment, aerated concrete wallboard equipment and autoclaved brick equipment in Shandong province.

With the full implementation of ISO9001:2008 Quality Management Systerm, Shandong Sunite Machinery was awarded with the title of Chinese Top Brand and Chinese Famous Brand and High-Quality Product in 2013.Besides, our company has also won several product patent awards.

2. Autoclaved Aerated Concrete

Autoclaved Aerated Concrete (AAC) is a siliceous material (sand, fly ash,gangue etc.) and calcareous materials (lime, cement) as the main raw material, mixing with foaming agent(aluminum powder) by mixing, casting, pre-curing, cutting, autoclave process made of light weight concrete products..

As a result of its excellent properties, AAC is used in many building constructions.

3. The material batching rate

NameUnitCement Lime SandSand%55-65Cement%10-20Lime%20-30Gypsum%2-3Aluminum powder paste(600kg/m3)1/100008Water & material rate 0.65-0.75Casting systemOC35-38Aluminum mixing timeS30-40

nameunitCement lime fly ashflash%65-70cement%6-15lime%18-25gypsum%3-5Aluminum powder paste(600kg/m3)1/100008Water & material rate 0.60-0.65Casting systemOC36-40Aluminum mixing timeS30-40

Remark:the exact batching rate is adjustable according to the raw material locally.

4.AAC production plant

a.AAC block making machine ---material treatment process

b.AAC block making machine batching ,mixing ,and pouring process

c.AAC block making machine foaming and curing Process

d. AAC block making machine—cutting and grouping Process

e. AAC block making machine---steaming and autoclave curing Process

| Name | Unit | Cement Lime Sand |

| Sand | % | 55-65 |

| Cement | % | 10-20 |

| Lime | % | 20-30 |

| Gypsum | % | 2-3 |

| Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

| Water & material rate | 0.65-0.75 | |

| Casting system | OC | 35-38 |

| Aluminum mixing time | S | 30-40 |