AAC Production Line/AAC Block Plant

SHANDONG KAIDONG CONSTRUCTION MACHINERY CO.,LTD(Include SHANDONG KAIQIAN IMPORT & EXPORT CO.,LTD and WEIDA MACHINERY CO.

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | AAC |

| Warranty | 1 Year |

| Operate Workers | 12 |

| Pallet Size | 1200X1000mm |

| Model | Fully Automatic |

| Brand Name | Kaidong Machinery |

| Color | Customized |

| Block Size | Length600mm, Width70-200mm, Height 100-300mm |

| Cutting Machine Size | 2m, 4.2m, 4.8m, 6m |

| Transport Package | Suitable for Shipping |

| Specification | 600x100x200mm, 600x150x200mm, 600x70x200mm |

| Trademark | KAIDONG MACHINERY |

| Origin | Shandong Linyi |

| HS Code | 8474802000 |

| Production Capacity | 100 |

Product Description

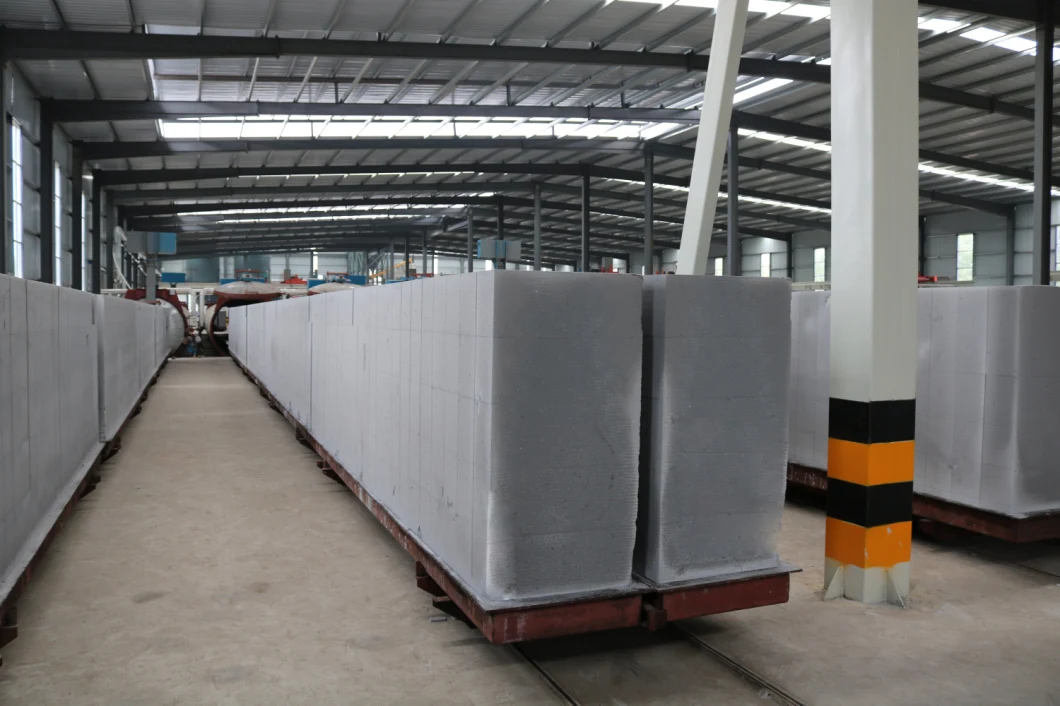

SHANDONG KAIDONG CONSTRUCTION MACHINERY CO.,LTD(Include SHANDONG KAIQIAN IMPORT & EXPORT CO.,LTD and WEIDA MACHINERY CO.,LTD) are professional building materials machinery and equipment research, manufacture and export company. Company business started from 1998, now our workers, sales and service branch staff are more than 300 people. Whole company year turnover is more than 50million USD. The company's main products are AAC block making machinery, concrete block making machine, concrete pole pipe making machine, concrete roof tile machine and mixers. The company passed ISO9001 management system and the European Union CE certification, the products absorb the German mechanical design and manufacturing experience, focus on quality design, high quality material, exquisite welding and strict inspection process to ensure high quality equipment and maximize service life. Company products are exported to Southeast Asia, Africa, South America, Eastern Europe, the Middle East, Australia and more than 100 countries and regions. Company of "integrity first, win-win cooperation", the positive development of quality products, improve the quality of service. We are not only the machinery products supplier, most important is that we are best program and service supplier according to clients' real conditions. Welcome all customers to visit us.1. AAC(Aerated Autoclaved Concrete Block Machine Line) (1)Introducation Areated concrete brick (light brick) is the light and porous buidling material. It has light keeping temperature cant burn and other advantages. It can be made into many kinds of bricks(for example: 600×200×100mm, 600×150×100mm, 600×300×200mm, 600×200×150mm), they could be used industry building and common building. They are more and more popular in the world. In the future, they will replace the clay brick completely. (2)Areated concrete common conception Common concrete density is usually 1600-2400kg/m3, but areated concrete are 500kg/m3, 600kg/m3, 700kg/m3. It has not the big grain, main use silicon material (for example: coal ash, sand, stone dust and others)through making the material small for example sand, they can be used directly if has enough degree of small(for example: coal ash). Mixing calcium material lime cement water to a special slop, then add the aluminum dust and the additive. Make the aluminum dust and the special slop have a Chemical reflect. Then produce Hydrogen to make the concrete slop to expanding or swell foam. Next, put them into the curing room to concreting cutting steaming curing. Finally, there will become the light brick. The porous rate is 70-80%. (3)Advantages Light weight Areated concrete density is usually 400-700kg/m3(according the market production), same as 1/3 of clay brick and 1/5 common concrete. So use the Light brick can reduce the weight of the build more ,and also reduce the beam of roof and pillar press best . then you can see, it can save the material and cost, it also fighting shaking. Keeping temperature It has many are porous, the delivery hearting coefficient is 0.9-0.22W/(mk), the same as 1/4 or 1/5 of clay brick, so it is best materials now in the world. Have many kinds material, have lowest waste Main Material: Sand/Flyash 65-70%, Cement 12-15%, Lime powder 12-15%, Gypsum 3-5%, Aluminum 0.5kg/m3 AAC block 2. AAC Line Capacity description: Main raw material: Silica Sand Cutting machine size: (1)2m cutting machine, 30000-45000m3/Year(100-150m3/Day), land requires 5000-8000m2 (2)4.2m cutting machine, 50000-150000m3/Year(160-500m3/Day), land requires 8000-15000m2 (3)4.8m cutting machine, 150000-240000m3/Year(500-800m3/Day, land requires 15000-20000m2 (4)6m cutting machine, 200000-300000m3/Year(700-1000m3/Day, land requires 25000-30000m2 Mould net size(after cutting):2x1.2x0.6/4.2x1.2x0.6m /4.8x1.2x0.6m / 6x1.2x0.6m Autoclave: Φ2x31.5m, Φ2.5x32m, Φ2.68x2m, depends on different capacity.3. AAC block reference material consume list(only for reference) AAC block model: B04 grade, average density 400-425kg/m3, pressure 2.0-2.5Mpa B05 grade, average density 500-525kg/m3, pressure 2.5-3.5Mpa B06 grade, average density 600-625kg/m3, pressure 3.5-5Mpa For example 550kg/m3 AAC block, we need the raw material list as following, just for reference, finial formula will be designed by engineers according to the materials that clients need.4. AAC material active ingredients analysis

| 1-1 Fly ash(65-75%) | |||

| Index item | Grade | ||

| I | II | ||

| Degree of fineness | 0.045 square hole sieve left amount | ≤30% | ≤45% |

| 0.080 square hole sieve left amount | ≤15% | ≤25% | |

| Ignition loss | ≤5% | ≤10% | |

| Silicon dioxide | ≥45-55% | ≥40% | |

| Sulfur trioxide | ≤1% | ≤2% | |

| Reference: The fineness can choose 0.045 or 0.080 square hole sieve left amount judge | |||

| 1-2 Sand(65-70%) | |||

| Grade | |||

| I | II | III | |

| Silicon dioxide | ≥85% | ≥75% | ≥65% |

| Chloride | 0.02% | 0.03% | 0.03% |

| Mica | ≤0.5% | ≤0.5% | ≤1% |

| Sulfur trioxide | ≤1% | ≤1% | ≤2% |

| Clay | ≤3% | ≤5% | ≤8% |

| Potassium oxide+Sodium oxide | ≤1.5% | ≤3% | ≤5% |

| 2 Lime(10-15%) | |||

| Item | Grade | ||

| I | II | III | |

| Calcium oxide+Magnesium oxide | ≥90% | ≥75% | ≥65% |

| Magnesium oxide | ≤2% | ≤5% | ≤8% |

| Silicon dioxide | ≤2% | ≤5% | ≤8% |

| Carbon dioxide | ≤2% | ≤5% | ≤7% |

| Digestion speed | 5-15 Minutes | ||

| Digestion temperature | ≥60-90 Degree Celsius | ||

| Undigested residue quality fraction | ≤5% | ≤10% | ≤15% |

| Fineness(0.080 square hole sieve left amount) | ≤10% | ≤15% | ≤20% |

| 3 Cement(10-15%) | ||||||||

| Silicon dioxide | Aluminium oxide | Iron oxides | Calcium oxide | Magnesium oxide | Calcium silicate | Dicalcium silicate | Tricalcium aluminate | Tetracalcium aluminoferrite |

| 21-23% | 5-7% | 3-5% | 48-64% | 4-5% | 44-59% | 18-30% | 5-12% | 10-18% |

| 4 Gypsum/Plaster(3-5%) | |

| Calcium sulfate | >70% |

| Magnesium oxide | <2% |

| Chloride | <0.05% |

| Preferably ground residue 90μm | <10-15% |

| 5 Aluminium Paste(0.074%) | |||||

| Species | Water formulation kind | Oil formulation kind | |||

| Item number | GLS-70 | GLS-65 | GLY-75 | GLY-65 | |

| Solid composition | ≥70% | ≥65% | ≥75% | ≥65% | |

| Activated aluminium in solid composition | ≥85% | ≥90% | |||

| Fineness | 0.075mm square hole sieve left amount ≤3% | ||||

| Gas produce ration | 4Minutes | 40-60% | 50-80% | ||

| 16Minutes | ≥90% | ||||

| 30Mintues | ≥99% | ||||

| Usually advice to use water formulation kind | |||||

Related Products

-

![Automatic Autoclaved Aerated Concrete AAC Block Plant]()

Automatic Autoclaved Aerated Concrete AAC Block Plant

-

![Keda Lightweight Concrete Block/Panel Making Machine, Automatic AAC Plant]()

Keda Lightweight Concrete Block/Panel Making Machine, Automatic AAC Plant

-

![2-4 Channel Small Bluetooth Multi-Home Audio System Equipped with Micro USB/TF, with a High- Efficiency Class-D Amplifier]()

2-4 Channel Small Bluetooth Multi-Home Audio System Equipped with Micro USB/TF, with a High- Efficiency Class-D Amplifier

-

![Progeneus Waterproofing Fiber Cement Board Autoclaving]()

Progeneus Waterproofing Fiber Cement Board Autoclaving