Concrete Mixing Plant 90m3/H Capacity Wet Mix Batching Plant with Good Price

Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 20000.000kg CONCRETE BATCHING

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Concrete Mixing Plant |

| Shotcrete Type | Dry |

| Machining Process | Hydraulic |

| Structure | Rotor Type |

| Productivity | 90cbm |

| Feeding Height | Customization |

| Vibrating Amplitude | 1.1mm |

| Certification | ISO9001: 2000, CE |

| Condition | New |

| Color | Orange |

| Discharge Height | 3.8m |

| Main Mixer | Js500-Js2000 |

| Batching Machine | PLD800-3200 |

| Cement Silo | 100ton/200ton/300ton(Optional) |

| Transport Package | Nude |

| Specification | standard size |

| Trademark | XINTU |

| Origin | China |

| HS Code | 847431 |

| Production Capacity | 3000 Sets/Year |

Packaging & Delivery

Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 20000.000kgProduct Description

CONCRETE BATCHING PLANT READY MIX CONCRETE MIXING PLANT

Brief Introduction:

Stationary concrete batching plant is widely used for small or medium-scale building construction, bridge and road construction, and prefabrication of concrete products. It has the advantages of less land occupancy, quick installation and convenient transportation.

Features:

1.This bucket type concrete mixing plant adopts twin shaft concrete mixer, it is with strong mixing power, high mixing evenness and high productivity.

2.The mixing blade and liner is made by high wearing-resistance chromium-manganese alloy, which is more durable with long lift span.

3.The PLD series aggregates batching machine have accumulated weighing or pneumatic independent weighing system for options.

4.The electronic weighting system has a buffer device and automatic volume compensation with high accuracy.

5.The complete set concrete batching plant use full auto control models by computer or full auto SIMENS PLC+PC model, meanwhile, we have PLC semi-auto control system or manual control system for options.

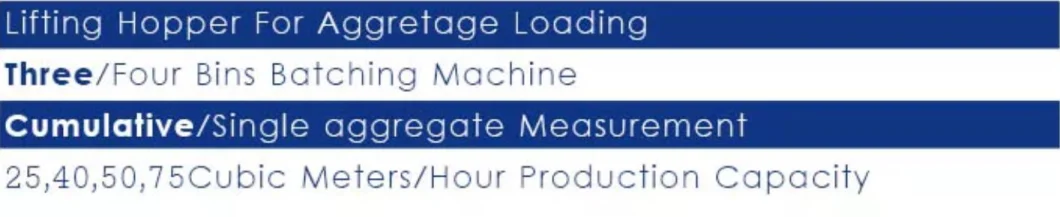

1.HZS BUCKET TYPE STATIONARY CONCRETE BATCHING PLANTPEODUCT PARAMETERS:

Model | HZS25 | HZS35 | HZS50 | HZS75 | |

Capacity (m³/h) | 25 | 35 | 50 | 75 | |

Mixer | JS500 | JS750 | JS1000 | JS1500 | |

Aggregate Bin | PLD800 | PLD1200 | PLD1600 | PLD2400 | |

Discharge Height (m) | 3.8 | 3.8 | 3.8 | 3.8 | |

Cycle Time (s) | 72 | 72 | 72 | 72 | |

Weighing Accuracy (%) | Aggregate | ±2 | ±2 | ±2 | ±2 |

Cement | ±1 | ±1 | ±1 | ±1 | |

Water | ±1 | ±1 | ±1 | ±1 | |

Additive | ±2 | ±2 | ±2 | ±2 | |

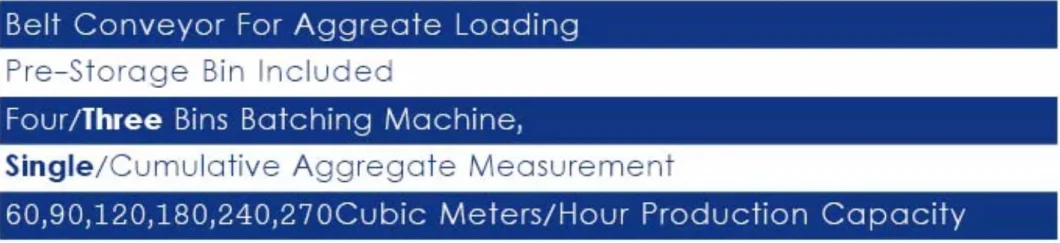

Theory Productivity(m3/h) | HZS60 | HZS90 | HZS120 | HZS180 | |

60 | 90 | 120 | 180 | ||

Standard Discharging Height(m) | 4.0 | 4.0 | 4.2 | 4.2 | |

Mix Cycle Time(s) | 60 | 60 | 60 | 60 | |

Total Power(KW) | 115 | 195 | 220 | 275 | |

Mixer Model | JS1000 | JS1500 | JS2000 | JS3000 | |

Batching Machine Model | PLD1600 pneumatic | PLD2400 pneumatic | PLD3200 pneumatic | PLD4800 pneumatic | |

Feeding Method | Belt | Belt | Belt | Belt | |

Weighing Accuracy | Aggregate | ≤2 | ≤2 | ≤2 | ≤2 |

Cement and Ash Coal | ≤1 | ≤1 | ≤1 | ≤1 | |

Water | ≤1 | ≤1 | ≤1 | ≤1 | |

Additive | ≤1 | ≤1 | ≤1 | ≤1 | |

MOQ | 1 set | 1 set | 1 set | 1 set | |

Delivery Port | Main Port of China |

Related Products

-

![Eco-Friendly Prebafrized House Rcb System with Alc Panel]()

Eco-Friendly Prebafrized House Rcb System with Alc Panel

-

![60cm Dual I3200 High Speed High Quality Digital Tshirt Printing with Powder Shaking Curing Machine]()

60cm Dual I3200 High Speed High Quality Digital Tshirt Printing with Powder Shaking Curing Machine

-

![2019 Year Dongyue Light Weight Block Machine / Fly Ash AAC Block Making Machine Plant]()

2019 Year Dongyue Light Weight Block Machine / Fly Ash AAC Block Making Machine Plant

-

![Lightweight Concrete Block Machine, Keda Automatic AAC Plant]()

Lightweight Concrete Block Machine, Keda Automatic AAC Plant