Automatic Dry Powder Mixed Concrete Cement Masonry Plaster Premix Mortar Concrete Mix Floor Ceramic Tile Adhesive Wall Putty Production Batching Mixing Plant

Overview Package size per unit product 1150.00cm * 210.00cm * 210.00cm Gross weight per unit product 11500.000kg Product

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | QC3000 |

| Control Type | PLC |

| Power Supply | Electric |

| Automatic Grade | Automatic |

| Shaft Type | Single |

| Layout | Horizontal |

| Voltage | Three Phase 230-415V |

| Number of Silos | up to 8 Per Production Line |

| Packing Machine | Automatic Filling and Sealing |

| Raw Material | Sand, Cement, Gypsum, Calcium Carbonate, etc. |

| Control System | Siemens PLC |

| Electric Parts | Siemens |

| Screw Conveyor | Wam Brand |

| Pneumatic Components | SMC Brand |

| Dust Collector | Pulse Bag Filter |

| Mixer Speed | 90rpm, 20ton/Hour |

| Reducer | Guomao Brand |

| Motors | Siemens or Wn Brand |

| Steel Structure | Detachable |

| Weighting Sensor | Toledo |

| Pneumatic Butterfly Valve | Wam Brand |

| Transport Package | by Container |

| Specification | 20x20 meter |

| Trademark | Qingchi |

| Origin | Shandong, China |

| HS Code | 847480 |

| Production Capacity | 1000 Sets/Year |

Packaging & Delivery

Package size per unit product 1150.00cm * 210.00cm * 210.00cm Gross weight per unit product 11500.000kgProduct Description

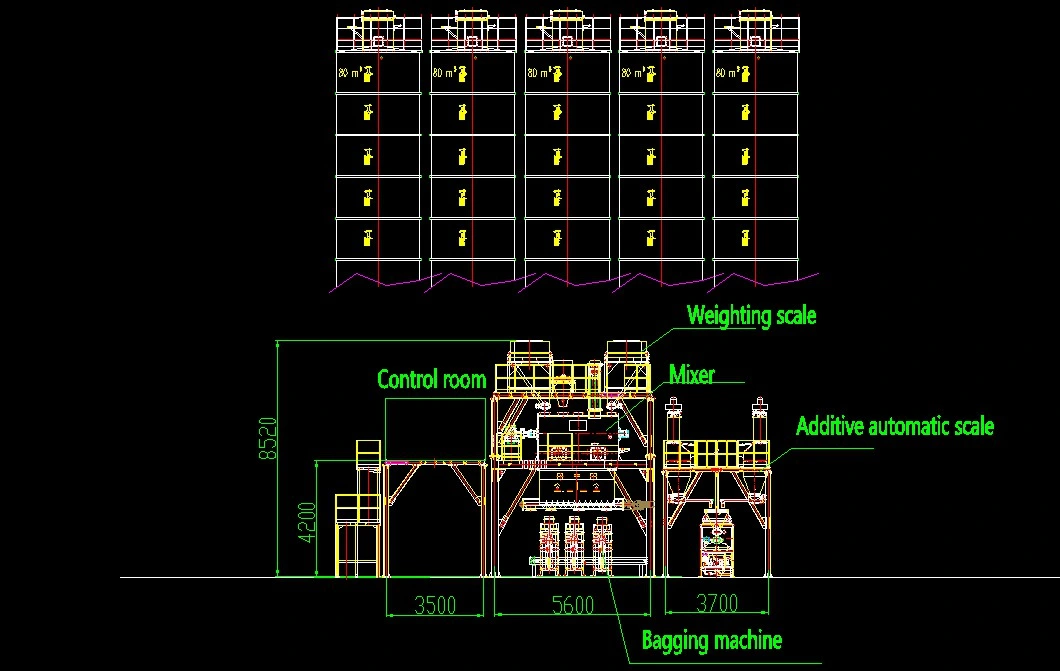

Dry powder mortar, also known as ready-mixed mortar, is made in the factory by precise batching and uniform mixing. It can be used directly by adding water on the construction site. Although different additives are added, it has different properties. The dry powder mortar plant has a production capacity of 15-150t/h. It can be fully automatic or semi-automatic. The plant structure type can be simple, automatic, or tower type. It depends on the customer workshop area.The large dry powder mortar production line includes a sand dryer and vibrating screen, storage bin, conveying system, weighing batching system, mixer, packaging machine, dust collector, and control system. According to customer requirements, we can design individual production processes.Application of dry powder mortar plant1. Bonding mortar:Tile adhesive, jointing agent, special adhesive mortar for thermal insulation composite system, etc.2. Masonry mortar:Ordinary masonry mortar, special thin mortar for concrete blocks, thermal insulation masonry mortar, etc.3. Decorative mortar:Exterior wall paint mortar, decorative plaster, interior, and exterior wall putty, color paint mortar, etc.4. Protective mortar:Waterproof mortar, anti-corrosion mortar, mildew-proof mortar, self-leveling mortar, wear-resistant mortar, soundproof mortar, etc.

Customer factory

In addition to the above schemes, our company also accepts the layout design of the entire factory. Complete packages are available upon request.

Detailed Photos

| Item | Fully automatic dry mix mortar production line |

| Capacity | 15-150 tons per hour |

| Application | Bonding mortar, Masonry mortar, Decorative mortar, Protective mortar, waterproof mortar |

| PLC | Siemens |

| Electric parts | Siemens |

| Weighing sensor | Toledo |

| Number of Silo | 2-5 sets |

| Bucket elevator | Plate chain bucket elevator |

| Screw conveyor | WAM brand, or Sicoma brand |

| Silo capacity | 100 tons |

| Additive system | Automatic control |

| Weighting tolerance | aggregate within +/- 1%, additives: within 20g |

Qingdao Qingchi Intelligent Technology is an industrial company engaged in the design, research, processing, manufacturing, and sales services of dry-mixed (powder) mortar production lines, special mortar production equipment, putty powder production lines, gypsum mortar equipment, and mortar construction equipment.

The company focuses on scientific and technological research and development and technical services and creates a non-standard customized manufacturer of special mortar and putty equipment.

Since its establishment, the company has been adhering to the tenet of promoting the enterprise through science and technology, people-oriented and the concept of integrity-based, pursuit of excellence; adhering to the style of advancing with the times, pioneering and innovative, and the management idea of simplicity, efficiency, and execution. Qingdao Qingchi Intelligent Technology has cooperated closely with many European companies and scientific research institutions in the same industry, integrating European advanced technology and years of practical experience, and developed a complete set of mortar production line equipment with advanced technology and reliable performance.

A: L/C, T/T, Western Union could be accepted.2: Can I visit your factory and your customer factory?

A: Yes, You can come by yourself or ask your friend in China to come to our factory or customer's factory.3: What about the delivery time?

A: 7-35 days after receiving the deposit. According to the number of non-standard parts.4: What about the warranty time?

A: 12 months after shipment or 2000 working hours.5. What about the Minimum Order Quantity?

A: The MOQ is 1 pcs.6. I don't have the formula, can you send me one?

A: Yes, we have more than 500 customers through these years, and our customers are willing to tell us their formulas.

Related Products

-

![Used AAC Block Plant Brick Block Machine Plant German Technology]()

Used AAC Block Plant Brick Block Machine Plant German Technology

-

![Sand Autoclave Aerated Concrete AAC Block Machine Plant]()

Sand Autoclave Aerated Concrete AAC Block Machine Plant

-

![Lightweight AAC Block Machine Manufacturer Autoclaved Aerated Concrete AAC Plant Block Making Machine Production Line]()

Lightweight AAC Block Machine Manufacturer Autoclaved Aerated Concrete AAC Plant Block Making Machine Production Line

-

![Darlly Majordepth Seires Capsule Filters Clarification Cell Stand with Autoclaving]()

Darlly Majordepth Seires Capsule Filters Clarification Cell Stand with Autoclaving