Adhesive Sealant Packaging Machine Adhesive Sealant Bathroom Automatic Cartridge Filling Lines

Adhesive Sealant Packaging Machine Adhesive Sealant Bathroom Automatic Cartridge Filling Lines Summary: 1. ZR brand auto

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | ZRM03 |

| Feed Cylinder Structure | Dual-Chamber Feeding |

| Dosing Device | Plunger |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Strongpoint | Easy to Open |

| Advantage | Easy to Maintain |

| Feature | Lower Power Energy |

| Application | Vicosity Material as Sealant,Adhesive,Pastes |

| Transport Package | Wood Case |

| Specification | Stainless Steel |

| Trademark | ZR |

| Origin | China |

| HS Code | 84224000 |

| Production Capacity | 20/Month |

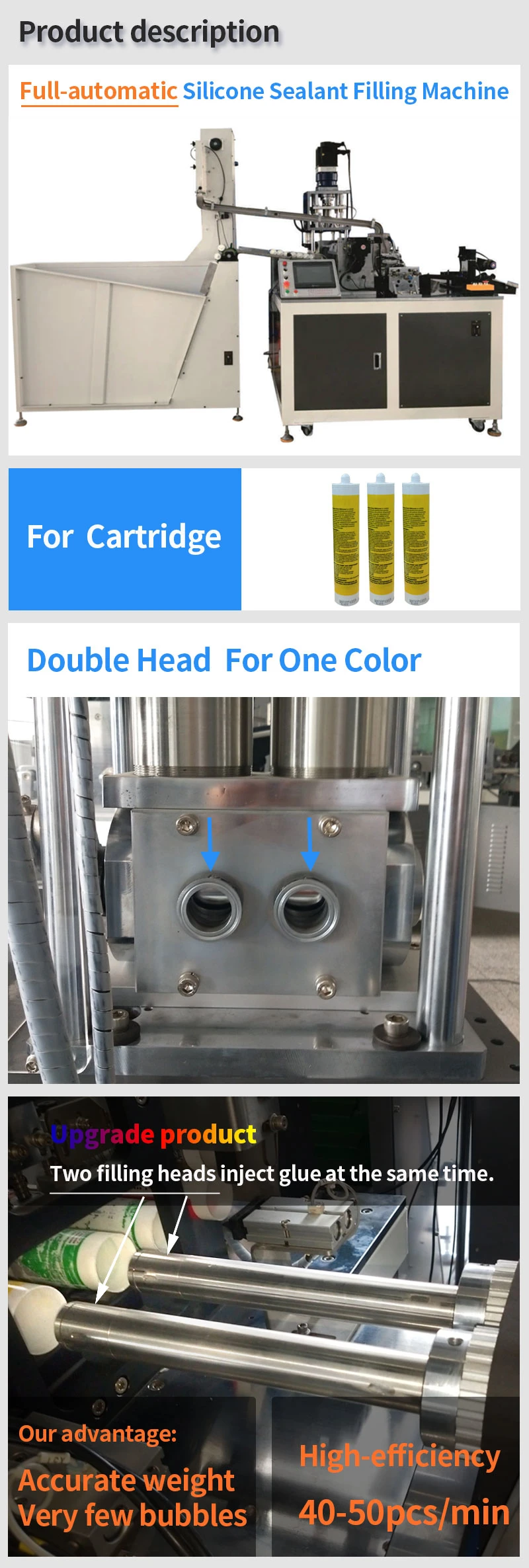

Product Description

Adhesive Sealant Packaging Machine Adhesive Sealant Bathroom Automatic Cartridge Filling LinesSummary:

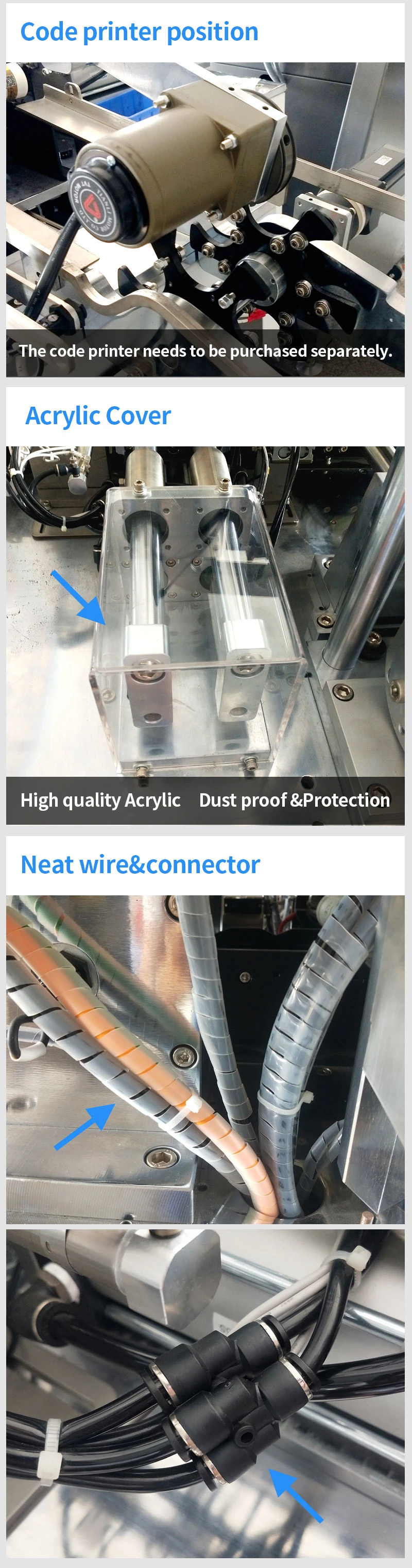

1. ZR brand automatic cartridge filling machine is kind of horizontal filling equipment filling silicone sealant, polyurethane sealant and such high viscosity materials in the plastic cartridge, paper tube and aluminum tubes etc.2. ZR brand filling machine is electro-pneumatic PLC machine, equipped with controls to reach maximum production speed and on-board diagnostics3. Its dosing unit with HORIZONTAL DUAL filling heads, for maximum flexibility independently from product features4. ZR brand filling machine has suitable to pack both in 310 ml (46 mm inner diameter) and 280 ml (44 mm inner diameter) cartridges, with few adjustments required to change format5. Suitable to pack of all kind of sealants, also bituminous and high temperature6. Filling volume adjustable from 260 ml to 310 ml (or other volume range by request)7. Cartridge's controlled lowering system during filling, to avoid any air incorporation8. Empty cartridges feeder with rejection of not correctly oriented cartridges, presence control and orientation control9. Plungers feeder with presence control10. Two closing steps: first one to insert the plunger in the cartridge, second one to press it (or to expand it in case of aluminium plunger), with total expulsion of residual air between plunger and product11. Controls to stop machine in case of lack of cartridge, lack of plunger or wrong cartridge's orientation12. Cartridge's automatic horizontal ejection system13. Production per hour/minute: abt. 2400/40 cartridges14. Machine dimensions: abt.2900*1600*2200Hmm 15. Machine net weight: abt. 1200 kg

Equipment Schematic Diagram

Production Information

| Speed: | 40-50 pcs / min | Power | 220V / 380V |

| Precision: | ±1g | Weight | 1.2 T |

| Air supply | 0.6-0.8 Mpa | Rate | 6 KW |

| Dimension | 2900*1600*2200 Hmm | Application | 260-310ML Cartridge |

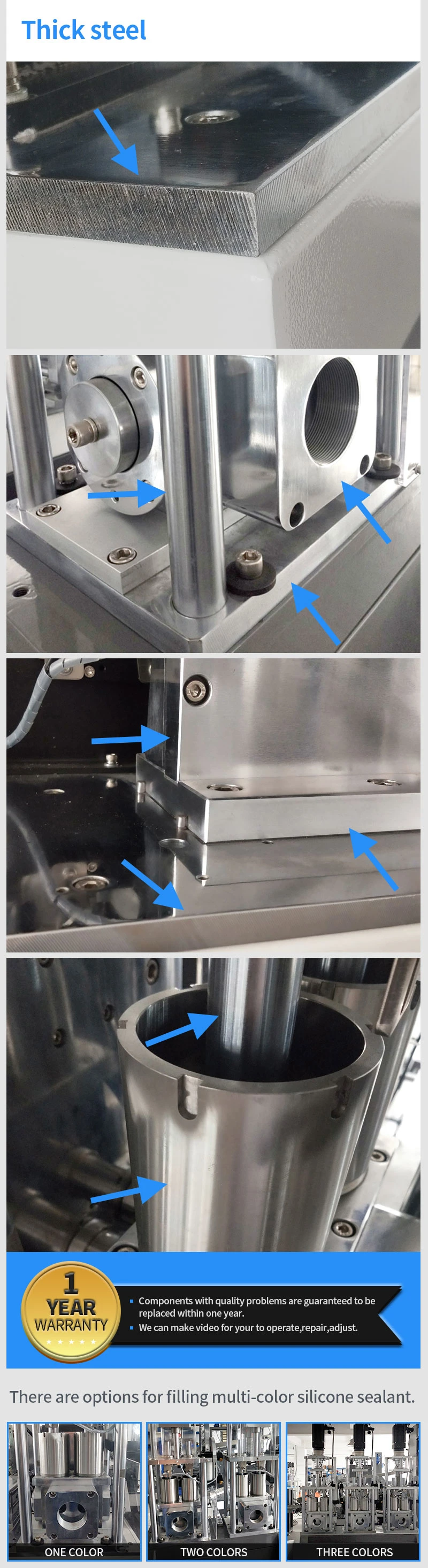

There are multi-option for filling machine for filling multi-color silicone glass glue.

Many options for assembly packing machine to implement the whole glass glue filling-packing automatic production line!

Contact us for solution!

After-Sale Service:

1) Free Training: Our factory can Freely train the user&technician for normal operations,maintaining.

2) Agent Services: Our Agent will give you services in time and professional guidances

3) Video: For some unexpected happens out of trainings,and our agent can not handle also, let us know your problems,we can make video for your to operate,repair,adjust etc.

4) Can give your supports from factory directly if necessary

5) Components with quality problems are guaranteed to be replaced within one year

6) Professional and Detailed product specifications for normal operations, problem solving,and maintaining

Our Company:

Related Products

-

![AAC Block Production Line AAC Block Plant Acc Factory Costs India]()

AAC Block Production Line AAC Block Plant Acc Factory Costs India

-

![Autoclaved Aerated Concrete (AAC) Light Weight Block Production Line]()

Autoclaved Aerated Concrete (AAC) Light Weight Block Production Line

-

![Semi Automatic Lipstick Filling Machine 12 Filling Nozzles Make Own Lipstick Lip Gloss Cosmetic Packaging Makeup Lipstick Tube Line]()

Semi Automatic Lipstick Filling Machine 12 Filling Nozzles Make Own Lipstick Lip Gloss Cosmetic Packaging Makeup Lipstick Tube Line

-

![Automatic Autoclaved Aerated Concrete AAC Block Plant]()

Automatic Autoclaved Aerated Concrete AAC Block Plant