Qgm High Productivity Fully Automatic AAC Production Line for Sale

AAC block Making Machine Autoclaved Aerated AAC lightweight Concrete Block Making Machine Line QGM designs and manufactu

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | AAC |

| Vibrating Amplitude | 2.4mm |

| Certification | ISO9001: 2000 |

| Condition | New |

| Transport Package | Standard Seaworthy Packing |

| Specification | CE & ISO9001 |

| Trademark | QGM |

| Origin | China |

| HS Code | 84748090 |

| Production Capacity | 300, 000 Cbm/Year |

Product Description

AAC block Making MachineAutoclaved Aerated AAC lightweight Concrete Block Making Machine Line

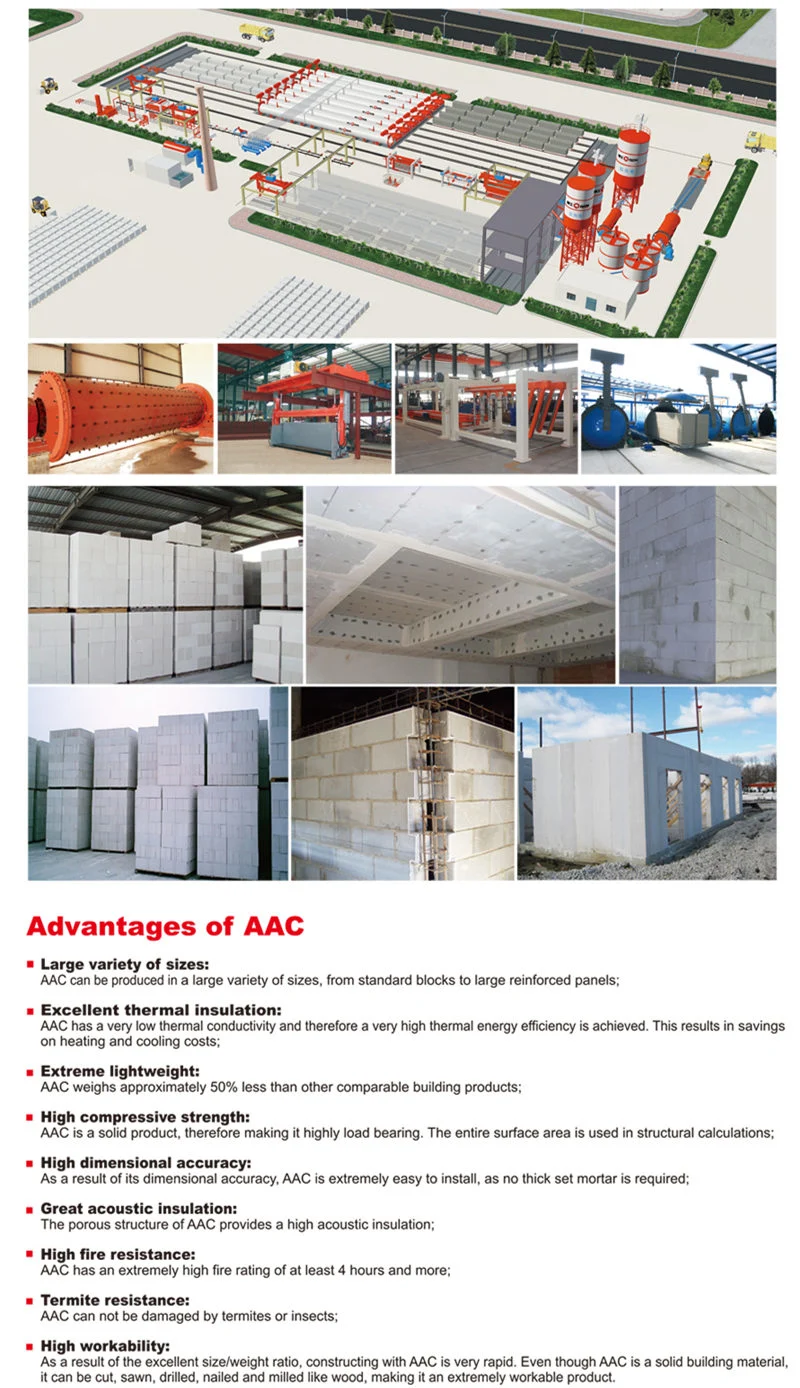

QGM designs and manufactures AAC block making plant, to meet the specific requirements of the market and cutstomers. As a new building material, AAC block fulfills the demand of concrete industry, which requires to save the natural resources and protect the environment. With Germany technology and our own R&D, we provide our customers state-the-art AAC block making plant.

1. Market Analysis

AAC is becoming more and more popular around the world, from western countries and then to developing countries. Below Properties make AAC have unmatchable property, especially for high buildings:

1) Extreme Light Weight

2) Large Variety of Sizes

3) High Fire Resistant

4) Excellent Thermal Insulation

5) Great Sound Insulation

6) Moisture Protection

7) Termite Resistant

8) High Workability and Easy Processing

AAC is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder ect., through batching, mixing, casting, cuttimg and autoclaving. AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great scousitc insulation and high fire resistance. AAC can be produced in a large variety of sizes, from stand blocks to large reinforced panels, and it can be cut, sawn, drilled, nailed and milled like wood, making it an extremely workable product, AAC is environment-friendly and new building material.

QGM Advantages:

Control System: Germany, Siemens PLC, main electrical components are from Germany Siemens, it

Weighing system are controlled by precise weighing system, guarantee the weighing accuracy. The accuracy will effect the qualified product rate, higher accuracy, higher qualified produce rate.

Steel silo storage, automatically control with arch breaker, level indicator.

With quality and service: A-Z Integrated solution for AAC brick making plant, the highly sophisticated manufacturing process.

QGM AAC Capacity:

Annual Capacity(300days) Power Daily Capacity Cycle Time No. Of Autoclaves

Annual Capacity(300days) | Power | Daily Capacity | Cycle Time | No. Of Autoclaves |

50, 000m³/year | 400KW | 166 m³/day | 10 hours | 2 |

100, 000m³/year | 500KW | 333m³/day | 10 hours | 4 |

150, 000m³/year | 630KW | 500m³/day | 10 hours | 6 |

200, 000m³/year | 720KW | 666m³/day | 10 hours | 8 |

300, 000m³/year | 1186KW | 1000m³/day | 10 hours | 6(D2.85*32.5) |

QGM ZENITH has set up overseas concrete block machine after-sales offices all over the world to guarantee the fast and high quality after sales service for global customers. There are 10 overseas offices for the after-market service of concrete brick machine, including Saudi Arabia, India, Dubai, Oman, Algeria, Nigeria, Zambia, South Africa, Vietnam, Indonesia etc.

Verified Information:

Since 1979, QGM specializes in concrete block machinery manufacturing and supply and is the only supplier that can supply integrated solutions for block making with our service and quality.

Quality Management System 6S, ISO9001, Environment Management system ISO 14001, CE certified, High Technology Corporate, 88 patents.

Established in 1953, ZENITH Maschinenfabrik GmbH (called ZENITH for short) is Germany-based concrete block machine manufacturer. Over the last 6 decades, ZENITH focus on the R&D of non-pallet block producing technology and today ZENITH has become the worldwide leader in non-pallet block machine manufacturing. Our product include: Mobile Multilayer Machines, Mobile Single Pallet Machines, Stationary Multilayer Machines and Stationary Fully Automatic Production Line.

Due to the highest quality and first class performance, more than 7, 000 ZENITH customers all around the world are continuous benefit from ZENITH's expertise and know-how day after day, for more than 60 years.

In July of 2014, ZENITH Maschinenfabrik GmbH was acquired by Quan Gong Machinery (called QGM for short), and become the member of QGM Group. QGM Group is able to provide a wide range products to our users, from simple automatic production line to fully automatic production line, from middle class to high class.

Related Products

-

![AAC Block Manufacturing Plant Supplier]()

AAC Block Manufacturing Plant Supplier

-

![UV Inkjet Coder Printing Machine for Food Traceability Spray Coder]()

UV Inkjet Coder Printing Machine for Food Traceability Spray Coder

-

![China Printer Manufacturer LED UV Inkjet Printer 2.5meter Dx5 UV Printing Machine]()

China Printer Manufacturer LED UV Inkjet Printer 2.5meter Dx5 UV Printing Machine

-

![High Quality Disposable Autoclaving Sterile Universal Plastic Laboratory Supplies Extended Length Racked Pipette Tips with Filter 10UL]()

High Quality Disposable Autoclaving Sterile Universal Plastic Laboratory Supplies Extended Length Racked Pipette Tips with Filter 10UL