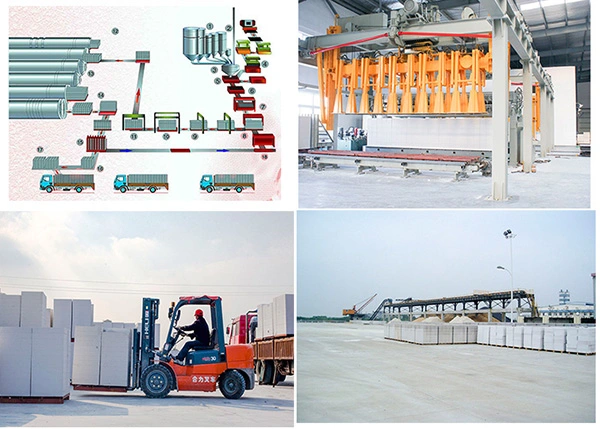

Environmental AAC Block Plant AAC Block Production Line

Description: Detailed Product Description High Quality AAC Block Equipment AAC Block Plant Autoclaved Aerated Concrete P

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | mingjie-0035 |

| Production Capacity | 100sets/Year |

Product Description

Description:Detailed Product Description

High Quality AAC Block Equipment AAC Block Plant Autoclaved Aerated Concrete Plant

What is AAC (Autoclaved Aerated Concrete) ?

AAC block (autoclaved aerated concrete block), also called Light Block which through the process of batching, pouring, pre-curing, cutting, autoclaving, separating and packing to make into the final products. AAC block is new type & environmental construction material and widely used for industry and civil building construction. It has light ,keeping temperature , Environmental protection,can't burn and other advantages. It has a wide prospect of market.it is the main building material in the future. AAC block can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building. AAC Block is the most mature technology of production and application in the worldwide nowadays. As normally, concrete density is usually 1600-2400kg/m3,but aerated concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain and use silicon material (for example: fly ash,sand,stone dust and others ),through making the material small for example sand, they can be used directly if has enough degree of small (for example fly ash, Mixing calcium material lime, cement, water to a special ratio, then add the aluminum dust and the additive, then Make the aluminum dust and the special ratio have a Chemical reflect. then produce Hydrogen to make the concrete slop to expanding or swell and foam. Next put them into the curing room to concreting cutting steaming curing, At last, there will become the light brick and the porous rate is 70-80%.

Features

1. The machine structure is simple and practical, the maintenance is easy;

2. The cake is sideward, so the width of the whole cake is 600mm, and the height is 1200mm. Steel wires for cutting is short, which is also difficult to rupture and float. It is high in cutting precision;

3. The vertical cutting device is fixed. Crosscut device cuts the cake vertically by steel wires. It shortens the cutting steel wires length, guarantee precision of cutting;

4. This machine cuts the green cake in Hexahedron-type, so the products quality wont be influenced by the distortion of the mould;

5. Cylinder Tension, which supply gas to each wire respectively;

6. Avoiding the wires being stretched off by using a special device;

7. Life of the wire can extend (Usually 10 days, Now 20 days);

8. Operating it in use of the computer touch panel, realize separation of Man-Machine.

Service

1. Production Line Design.

Including: drawing of plant working process,drawing of land construction,drawing of power working, drawing of driving force for working,drawing of anti-dust,drawing of water supply and drainage and drawing of air pipeline construction.

2. Technical Guidance of Building Factory

Including consultation of facility, Equipment installation guide, constitution the production preparation, etc.

3. Providing the technical information of setting up factory

Including: part of the factory management system, all posts accountability of production line, process rules, safety rules, setting a quota of staff and posts, pre-production tools directory, laboratory instruments, product catalogs, and test methods.